An additional task assumed by the steel industry, one that is incidental to the Voluntary Action Program, aims to reduce energy consumption by another 1.5% through the effective use of plastic waste in blast furnaces, coke ovens, etc.-assuming that appropriate methods of collection and other necessary systems for plastic waste recovery can be established.

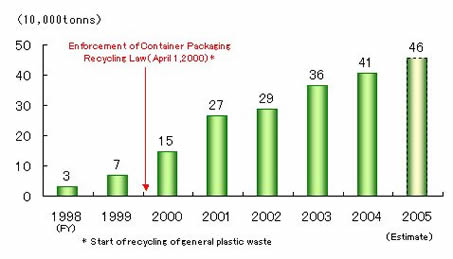

The utilization of plastic waste materials categorized as industrial waste has been promoted since 1997. Similarly, subsequent to the full-scale enforcement of the Container Packaging Recycling Law of April 2000, the use of plastic waste materials categorized as general waste has proceeded at a quickening pace. The total amount of plastic waste treatment result in 2004 reached 410,000 tons.

The steel industry is presently reinforcing its ability to treat plastic waste and has set a target capacity of one million tons for 2010.

The steel industry effectively reuses both industrial and municipal plastic waste by recycling them into usable materials. It employs primarily two kinds of recycling technology: one is the injection of plastic waste into blast furnaces where it is used as a reducing agent, while the other is to charge plastic waste into coke ovens where it decomposes into hydrocarbon resins (tar and light oil), coke used as a reducing agent in blast furnaces, and coke oven gases.