The steel industry's measures against global warming in the Voluntary Action Program comprise the following five major approaches:

・Efforts to save energy in iron- and steelmaking processes

・Effective utilization of plastic and other waste materials (premised on the establishment of appropriate collection systems)

・Contributions to energy savings in society with steel products and by-products

・Contributions to energy savings through international technical cooperation

・Utilization in areas around steelworks of energy unused in iron- and steelmaking

The steel industry has set a 10% reduction in energy consumption as its goal for the year 2010 compared to 1990 levels(on the assumption of the crude steel production 100 million-ton level).

The industry is also committed to achieving another 1.5% reduction through additional measures such as the effective use of plastic waste in blast furnaces, coke ovens, etc.-assuming the establishment of appropriate collection methods and other necessary systems.

PJ: Petajoule (1015 joules); 1 cal.: 4.18605J; 1 PJ: About 25,800 kiloliters in crude oil equivalent

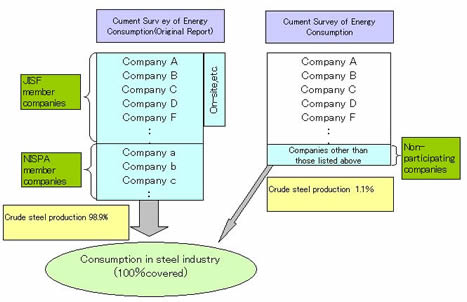

As of the end of fiscal 2004, a total of 68 companies were participating in the Voluntary Action Program. Together, these firms account for 97.4% of all energy consumed by the steel industry.

However, the follow-up survey achieved 100% coverage by using national statistics to obtain relevant data on non-participating companies.

*Voluntary Action Program for Environmental Protection by Steelmakers

A PDCA (plan-do-check-action) scheme has been prepared as a review system within the steel industry and is reexamined annually by the governmental Steel Working Group of the Joint Follow-up Subcommittee, Research Committee on General Resources and Energy of the Industrial Structure Council. By the Nippon Keidanren, too.

The steel industry examined measures for enhancing the clarity and reliability of the Voluntary Action Program from October 2001 onward. As a result, the work of computing data going back to 1990 in the follow-up was modified as follows:

1) Clarification of the steel industry boundary

2) Adoption of national statistical indexes (unit calorific value, CO2 emissions coefficient)

3) Adoption of international units (SI units, e.g. joules etc.)

The national statistical index for unit calorific value in 2) was redressed from 2000 to reflect the growing use of low-grade coking coal and coal used for PCI (pulverized coal injection) after 1990.

Note: → Energy input in the boundary of steel industry,→ Energy subtraction

→ Energy movement between equipment

IPP: Independent Power Producer