Energy consumption in the steel industry is decreasing due to improved energy-saving measures. Energy consumption in 2004 amounted to 2,371 PJ (equivalent to 61.2 million kiloliters in crude oil), a decrease of 4.4% from 2,479 PJ in the base year of 1990.

Note PJ: Petajoule (1015 joules); 1 cal.: 4.18605J; 1 PJ: About 25,800 kiloliters in crude oil equivalent

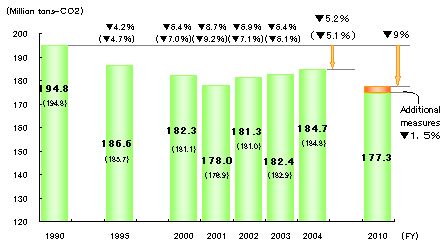

Rough evaluations show that energy-related CO2 emissions amounted to 184.7 million tons in 2004, a decrease of 10.1 million tons from the 1990 level.

Note: Figures in the parenthesis are those reflecting the annual CO2 emission coefficient of electric utilities.

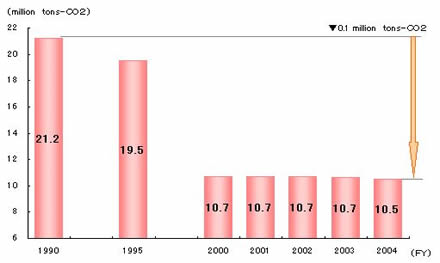

The steel industry uses limestone and dolomite as auxiliary raw materials (non-energy materials) in blast furnaces and basic-oxygen furnaces in order to remove the impurities contained in iron ore.

The consumption of limestone and dolomite is declining due to improvements in the quality of the sintered ore charged into blast furnaces and to reductions in the generation of slag in basic-oxygen furnaces. Because of operational improvements such as these, CO2 emissions are also decreasing.