Action by the steel industry: data collection

Overview

Details of Data

- Function and Functional Unit

- System Boundary

- Data quality

- Participating companies

- Calculation of an average value

- Assumptions of methodology and handling of co-products

- Data format

- Recycling Rate

- Precautions

- Data request

Overview

-

The Japan Iron and Steel Federation (JISF) conducts a highly comprehensive, representative and transparent LCI study in accordance with ISO 20915, JIS Q 20915, ISO 14040 and ISO 14044 standards, based on the data collected by its member steel manufacturers on a regular basis. The published result are Japanese average data.

The Japanese average LCI data for steel products disclosed here is the result of LCI data collection and calculation with the methodology according to the ISO 20915 standard and JIS Q 20915, the methodology common to the global steel industry. The Japan Iron and Steel Federation collected primary data based on the actual operation in steel mills for fiscal 2022 and calculated the Japanese average LCI values for each steel product in the LCA Study Working Group of the Technology Policy Committee.

Please click here to inquire about the world average LCI data from worldsteel.

Details of Data

- Function and Functional Unit

-

One kg of a steel product at the factory gate is used as a functional unit.

The LCI study was applicable to the varieties of steel products shown in the table below. Detailed specifications such as size range, dimensions, plating thickness, strength, etc. within each type vary in actual manufacturing, but they are averaged values for the entire product.teturenn.

Figure 1: Product Types

Product Name

Product Description

Main Applications

1

Hot rolled coil

Steel sheet rolled on a hot-strip mill to a thickness of 1.2 to 25.4mm. Width ranges from 600mm to 2,300mm.

Large automobile vehicles, railroad vehicles, various containers, bridges, roofing materials, guardrails, etc.

It is also used as a material for cold-rolled steel sheets, surface-treated steel sheets, welded steel pipes, and lightweight steel shapes.2

Pickled hot rolled coil

Hot-rolled steel from which the iron oxides present at the surface have been removed in a pickling process.

Used for large automobile vehicles, railroad cars, various containers, bridges, roofing materials, guardrails, etc.

It is also used as a material for cold-rolled steel sheets, surface-treated steel sheets, welded steel pipes, and lightweight steel shapes.3

Cold rolled coil

Pickled steel sheet rolled thin at room temperature.

Automobiles, electrical equipment, steel furniture, etc.

Used as a material for tinplate, galvanized steel sheet, etc.4

Finished cold rolled coil

Produced by annealing process from cold-rolled steel sheet. Crystallization is controlled, and formability is improved.

Automobiles, electrical equipment, steel furniture, etc.

Used as a material for tinplate, galvanized steel sheet, etc.5

Electrogalvanized steel

Surface-treated steel sheet with superior corrosion resistance by plating the surface with zinc.

Obtained by electro plating.Automotive, construction, etc.

6

Hot-dip galvanized steel

Plated steel sheet manufactured by immersion in hot-dip zinc.

Automotive, construction, etc.

7

Tin-free (ECCS)

Also known as Electrolytic chrome coated steel (ECCS). Obtained by electroplating a thin finished cold-rolled coil with a thin layer of chrome.

Good adhesion to paint, film, etc.

Used in the same way as tinplate steel sheet.Food cans, beverage cans, etc.

8

Tinplate

Tin-plated steel sheet. Corrosion-resistant and excellent in workability.

Food cans, beverage cans, etc.

9

Organic coated

Coated steel sheet with added functions such as scratch resistance and stain resistance.

Home appliances, construction, etc.

10

Plate

Hot-rolled steel plate with a thickness of 6 mm or more.

Ships, marine structures, architecture, bridges, tanks, pressure vessels, various plants, etc.

11

Welded pipe

Small- to medium-diameter pipes made by forming steel plates into a cylindrical shape and welding them together.

Automotive pipes, structural pipes, steel pipes for plants, line pipes, etc.

12

Sections

A steel material with a variety of cross-sectional shapes to suit different purposes. Includes H-beams, angle steels, I-beams

Construction, bridges, wharves, ships, vehicles, etc.

13

Steel Bar

Steel in the form of a bar. Steel bars are used as reinforcing bars at construction sites and as structural materials for machinery, ships, etc.

Construction, machinery, etc.

14

Wire rod

Steel material formed into a wire shape by hot rolling with a cross-sectional diameter of about 5 mm to 50 mm.

Materials for steel wire, wire, wire springs, tire cores, etc.

15

Engineering steel (Tool steel)

Steel that has characteristics such as hardness, strength, tenacity, abrasion resistance, heat resistance, and corrosion resistance by adding alloying elements.

Automobiles, tools, etc.

- System Boundary

-

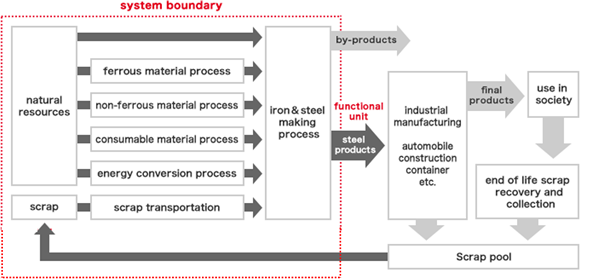

The scope of this study covers from the mining of raw materials to the shipment of steel products. As shown in the figure below, the system boundary includes all activities within the steelworks and the main upstream processes, including production and transportation of raw materials, energy sources, consumable materials used at steelworks. It does not include the assembly and manufacture of the final products (e.g. automobiles) and use of those final products.

Steel products are collected as ferrous scrap after the end-of- life of the final product and are used again as a raw material for new steel products (closed-loop recycling). For this reason, scrap recycling is also included in the system boundary in this study.

In addition, collection and use of steel co-products (by-products) outside the steelworks was evaluated using the system expansion method.

Figure 2: System Boundary in This LCI Study

- Data quality

-

Steelworks data

Basically, data is collected based on measurement, calculation, and purchase records.

Upstream process data

In general, data from processes outside of the steel industry, such as upstream processes before entering the steelworks and co- or by-product utilization outside the site, relied on the secondary data such as LCI database and literature dedicated to that field.

In most cases, GaBi database provided by Sphera Solutions GmbH is used.

Time coverage

It mainly consist of operational performance data from April 1, 2022 to March 31, 2023.

Geographic range and product coverage

Companies participating in this data collection account for about 85% of crude steel production in Japan and can be regarded as representative data of Japan.

- Participating companies (at the time of data collection)

-

Aichi Steel Corporation, Itoh Iron & Steel Co., Ltd., Osaka Steel Co., Ltd., Kyoei Steel Ltd., Godo Steel, Ltd., Kobe Steel, Ltd., Sanyo Special Steel Co., Ltd., JFE Steel Corporation, Shimizu Steel Co., Ltd., Daido Steel Co., Ltd., Tokyo Kohtetsu Co., Ltd., Tokyotekko Co., Ltd., Topy Industries Limited, Nippon Steel Corporation

- Calculation of an average value

-

The average value of multiple companies takes into account the amount of production, by calculating a weighted average value of LCI of individual processes, and summarizing the LCI of each process.

- Assumptions of methodology and handling of co-products

-

Please refer to notes on individual items

Electricity

For the grid electricity, Japanese data for the year 2022 was adopted from the LCI database.

Pretreated raw materials

For pre-processed raw materials such as coke, sintered ore and pellets, etc. procured from the outside, their respective global average values were allocated.

External transport

We decided the transportation distance on the premise of ship transport between representative production sites of each raw material (iron ore from Brazil, coal from Australia) and representative receiving port of Japan (Nagoya). The data associated with scrap transportation is also included.

Handling of co-products

In a multiproduct production system, allocation rules must be determined in association with system inputs and outputs for each product. Various co-products and by-products (collectively ‘co-product’ hereinafter) are produced in the production process of steel products and are effectively used. In ISO 14044: 2006 standard (4.3.4.2), recommends to divide the process for each product in order to avoid allocating the load to co-products. However, co-products produced by steel production are produced in the same process as steel products and cannot be separated. For this reason, in this LCI data, the system expansion method recommended in ISO 14044: 2006 standard (4.3.4.2) was applied to the co-products. The alternative system for system expansion of each co-product is as follows. For each system, we evaluated the input substituted by the use of co-products and the output associated with it.

Blast furnace slag: roadbed material production, cement clinker production, fertilizer production

Converter slag: roadbed material production, cement clinker production, fertilizer production

Electric arc furnace slag: roadbed material production, cement clinker production, fertilizer production

Process gas (CO gas, BF gas, BOF gas): Power generation to which the process gas is supplied, or electricity generation based on Japanese power supply composition - Data format

-

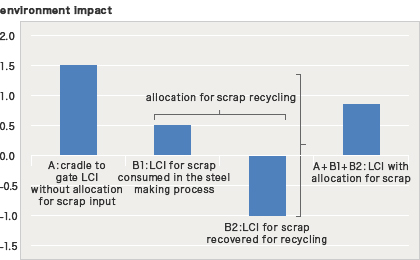

LCI data is provided in three components as shown in the figure, considering the possibility of use for applications using modularity principle.

Figure 3: Illustration of LCI of steel products

LCI of steel products reflecting the effect of scrap recycling = A + B 1 + B 2

where

A:cradle to gate LCI without allocation for scrap input effect

B1:LCI for scrap consumed in the steel making process = scrap LCI ×yield of scrap recycling process

B2:LCI for scrap recovered for recycling = -scrap LCI × recycling rateThe total of B1 and B2 is the scrap recycling effect.

Since scrap recovery and scrap consumption are inseparable in scrap recycling, it is not possible to evaluate A + B1 only or A + B2 only.Figure 4: An image of data format

LCI of steel products reflecting the effect of scrap recycling

Cradle to gate LCI without allocation for scrap input

scrap recycling effect

burden associated with scrap consumption

credit associated with scrap recovery

A+B1+B2

A

B1

B2

example

60

100

20

-60

- Scrap LCI

-

Steel products are collected as scrap after the end-of-life of the final products (such as automobile) and are used again as raw materials for new steel products (closed-loop recycling). Therefore, in this LCI data, the effect of scrap recycling (scrap recovery and consumption) is also evaluated. Since scrap replaces the resources necessary for the steel production, and we defined this substitution effect as the inventory of scrap (scrap LCI:LCI of 1 kg of scrap).

The scrap LCI was calculated based on the ISO 20915 standard and JIS Q 20915 using the following formula.

Scrap LCI = (LCI of producing 1 kg of crude steel without steel scrap - LCI of producing 1 kg of crude steel only from steel scrap) × yield of producing crude steel only from steel scrap*

* Crude steel production per 1 kg of scrap input

Data for the calculation (LCI of 1 kg of crude steel production using 100% natural resources, LCI of 1 kg of crude steel production using 100% scrap, and yield of crude steel production using 100% scrap) were based on FY2022 Japan actual average values.

If you would like to use the scrap LCI in this study, please contact us using "data request form" at the bottom of the page.

- Recycling Rate

-

In calculating the LCI of steel products, a recycling rate is necessary. The recycling rate is calculated according to the following equation, according to ISO 20915.

Recycling rate = (amount of manufacturing scrap recycled + amount of end of life scrap recycled) / amount of steel products shipped from steel worksThe recycling rate of steel products was estimated to be 93.7%, referring to the actual recycling rate of steel cans in FY2022 (92.7%, source: Steel Can Recycling Association) and the estimated processing yield of steel products in FY2022 (86.4%, source: estimated from Tetsugen Association data).

For details on calculating the recycling rate, please refer to ISO 20915 Annex E.

- Disclaimar

-

Due to different calculation conditions, etc., this LCI is not comparable to LCI of steel products in other databases or LCI of other materials.

Since the data is organized for each steel product, it cannot be used for the purpose of calculating emissions from the steelworks. Likewise, it is not suitable for evaluating emissions from manufacturing processes.

Since the data is created from measurable or estimable data, inventory items that can be evaluated are limited.

This data represents the values before steel manufacturers allocate the Reduced Emissions of Product to Green Steel, based on JISF's "Guidelines for green steel"(*).

(The value do not take the allocation of Reduced Emission of Product into account.)

JISF assumes no responsibility for any direct or indirect damage arising from the use of this data.

(*) JISF's "Guidelines for green steel" is available only in Japanese as of March 2025. - Data request

-

The Japan Iron and Steel Federation provides LCI data to those who conduct LCA of products using steel products.

If you would like to use LCI data, please fill out the form and send it to kankyou1@jisf.or.jp